PdM APPLICATION

A solution to shift to modern ways of predictive maintenance is to create a Digital Twin of the equipment and

generate sensor data for various fault conditions through simulation...

Self-sufficient

Presently gather Predictive Maintenance information without human mediation and mistakes, 24 x 7. Save the time your group spends on information assortment by means of an App.

Beyond the time barriers

Our PdM Predicts and help you in distinguishing machines that need consideration. The region where they need consideration. The development scientific instruments can assist you with doing fast and backing your choices.

AI Tehnology

This product is derived from Artificial Intelligence which is one of the modern branches of today science. AI has helped many industries to change and AI era is called another revolution in human science history.

Cost Management

We have utilized the most recent innovation while finding some kind of harmony among cost and components. It is intended to finish the work with less cost, successfully.

Expand over the Time

Any IT and specially AI related product has ability to improve as IT technology improves over the time. Let alone the Machine Learning character of this product. In other words, as the time goes by, the data mined, coming out of Big Data, obviously improves the efficiency of the product.

Any place

Presently access your machine's well-being and symptomatic information from anyplace utilizing a cell phone.

Basic Technologies

IoT technology

Internet of Things is the very important today topic of connection of various industrial parts over the internet to each other. That is the 5G and 6 G internet challenge which is making huge improvements possible through sensors and transmitting the data over internet as per defined protocols for this purpose. From a smart home upto a smart factory like Nissan are all depended to IoT and PdM is also the same.

Artificial Neural Networks (ANN)

The recorded information is used to train a machine learning model; in this case, the Artificial Neural Networks (ANN); which is used as a Digital Twin (DT).

ANN is used to classify the outcome and be utilized for predicting the fault type and predicting the breakdown time. A time-series method is used within an ANN that is capable of predicting recurrence.

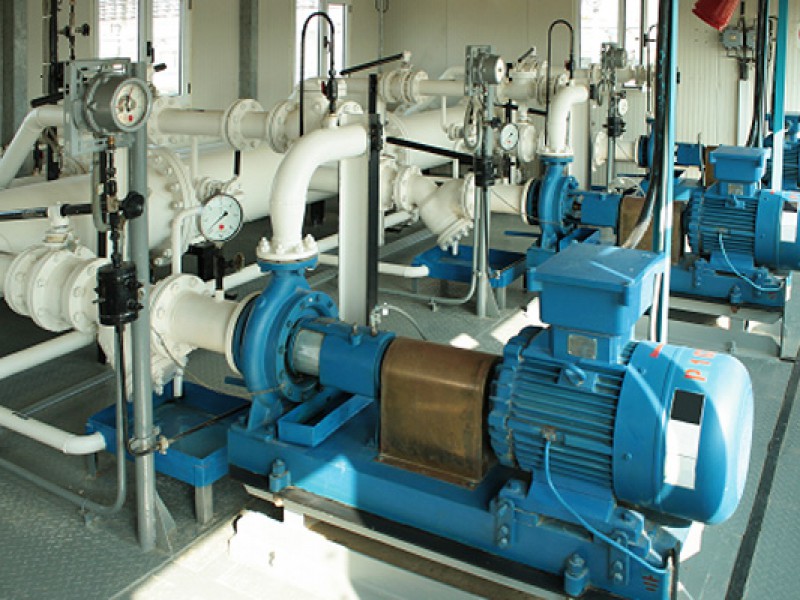

Innovative Predictive Maintenance

An innovative Predictive Maintenance (PdM) procedure is proposed. In this novel technique, sensors are connected to the system’s operating parts and some parameter values (such as pressure, vibrations, temperature) are always being measured and recorded for each system element by IoT technology.

Digital Twin (DT)

The D.T. can predict the time and type of break down before it happens. Therefore, it can prevent both system failures and early part replacements. It helps to avoid production rate reduction as well as unnecessary replacement costs. The trained model’s performance is gradually boosted as more data is logged in the system. Besides, different plants can share their data on the cloud to help each other’s D.T.’s quality by increasing the data volume.

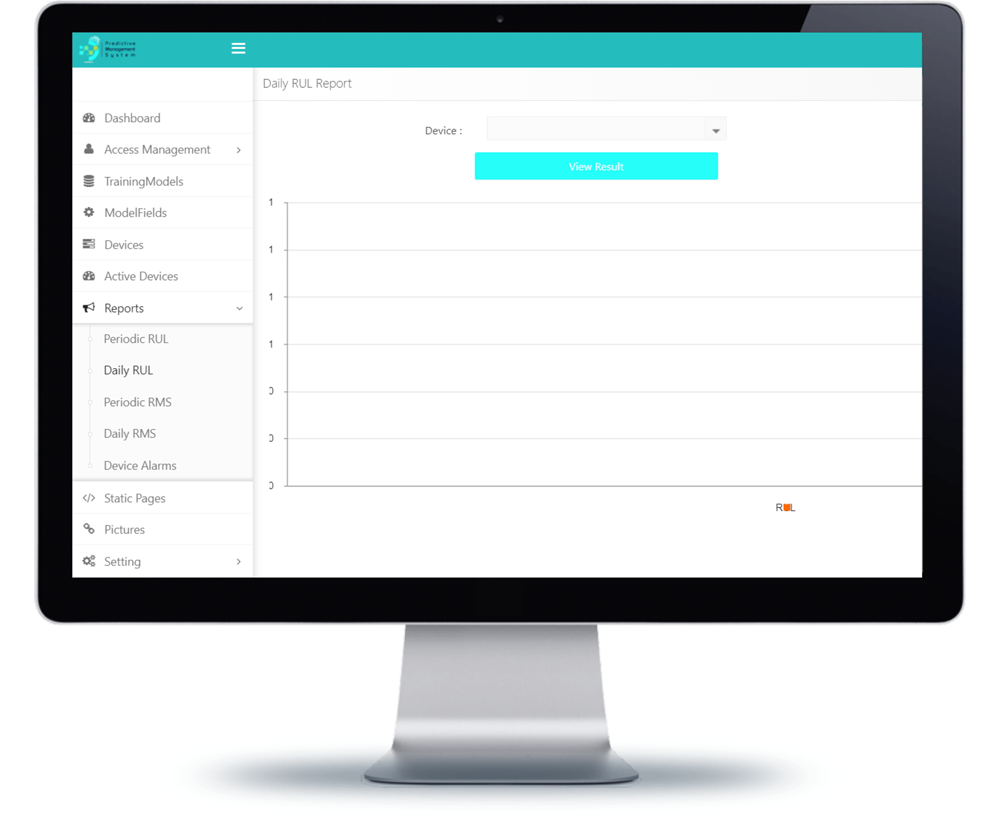

PdM Product (version 1.02.2021)

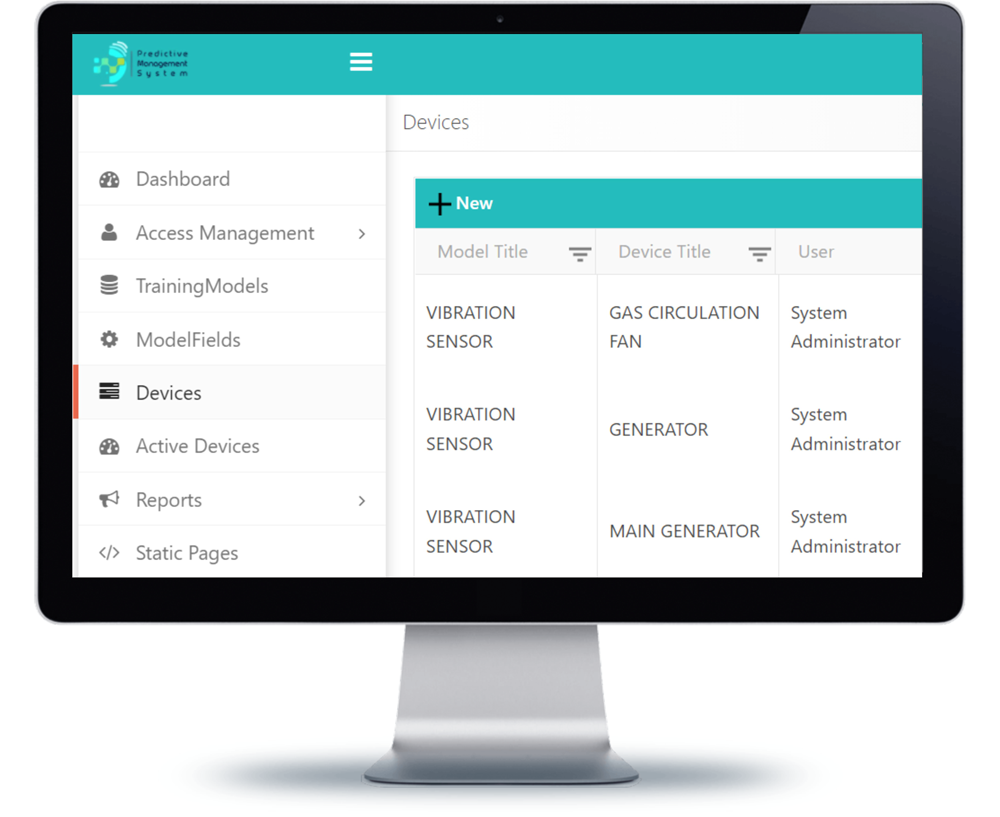

PMS Features

-Administration dashboard settings

-Back up and restoration ability

-File management

-Organization definitions

-Roles definitions for users as per:

* Admin

* Supervisor

* User

-Access permission to users for each page

-User(s) profile definition

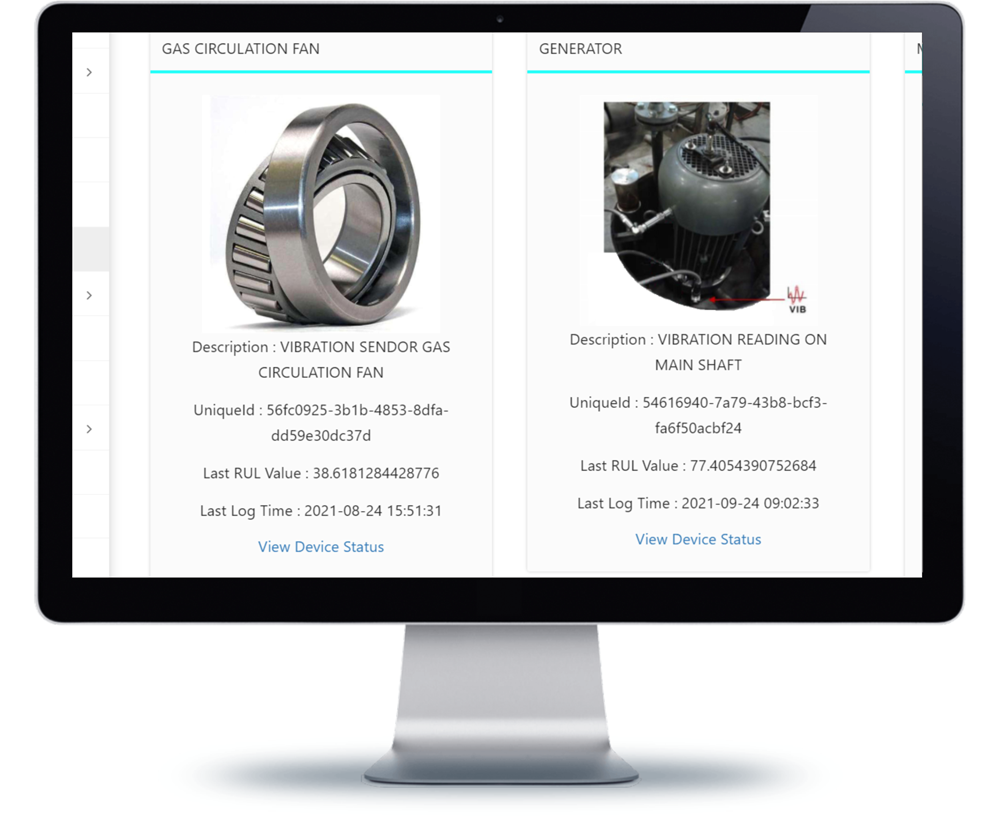

*Name of Equipment

*Equipment Information and Details

*Equipment Image

*Equipment Train Data with RMS input data and RUL output data

*Watching the Trained Values (Train, Validation, Test) & ability of Re-training

-Predictive Section including:

*Selecting one or some Equipment

*Communicating Configuration and Protocol Definition

*Warning Threshold

*Warning Settings including:

"Email(s) Definition

"SMS Number(s) Definition

-Administration dashboard reports with settings ability

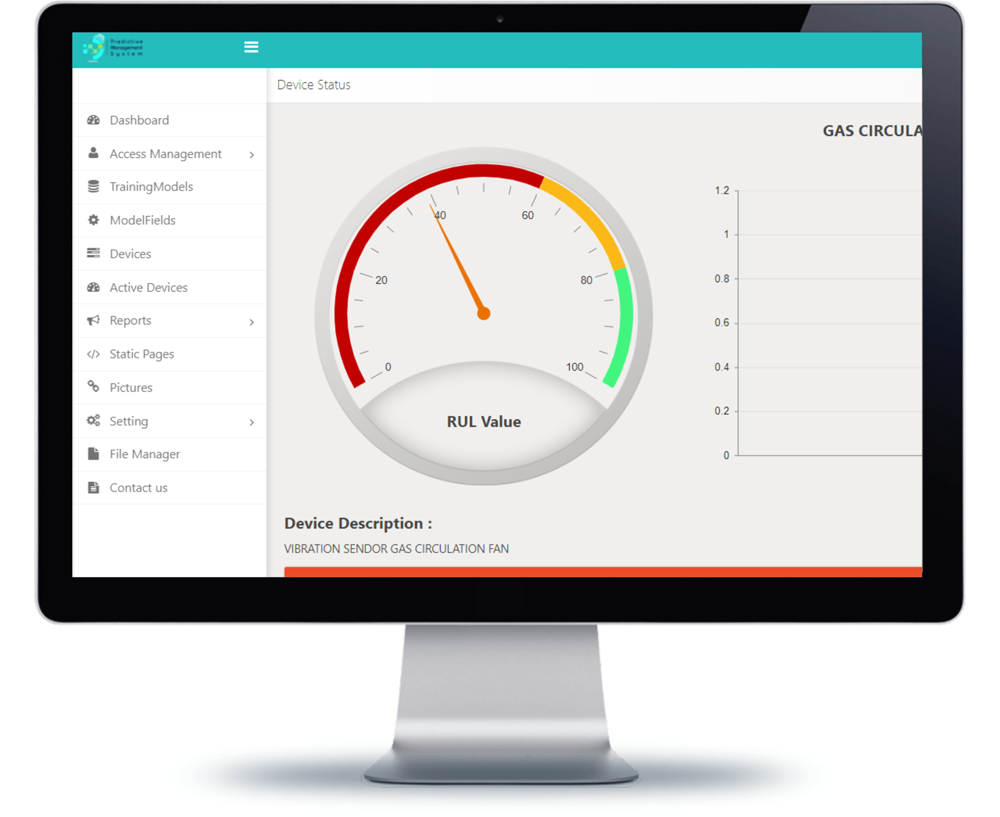

*Connected Equipment

*Defected Equipment

*Live Chart of RMS and RUL

*and …

-Sent warning information report