Let’s talk about the very huge investment for a Tunnel Boring Machine (TBM) working for aMetro company in a Luxurious City like Dubai.

Signing a contract between Dubai Road Authorities and Mitsubishi Heavy Industries by a millions of dollars deal, a TBM was sent to Dubai to be used for some tunnels. Needless to say, working each second is precious in such a weather of UAE due to bad climate conditions. Thus the TBM should work 24X7. It means the best available methods of maintenance should be used. Among them we have Vibration Analysis, Thermography and Oil Analysis.

In Vibration analysis, the health of the machine based on collected data are analyzed. This allows the changes within the machine to be determined precisely and appropriate corrective action can be initiated. Vibration analysis is chosen for several reasons. The measurement of vibration is still a very effective tool to determine machine condition, especially since it can detect abnormal operating conditions long before there is any permanent damage to the machine.

Thermography also shows the under stress parts of the machine while Oil Analysis shows if any part is under wearing and corrosion.

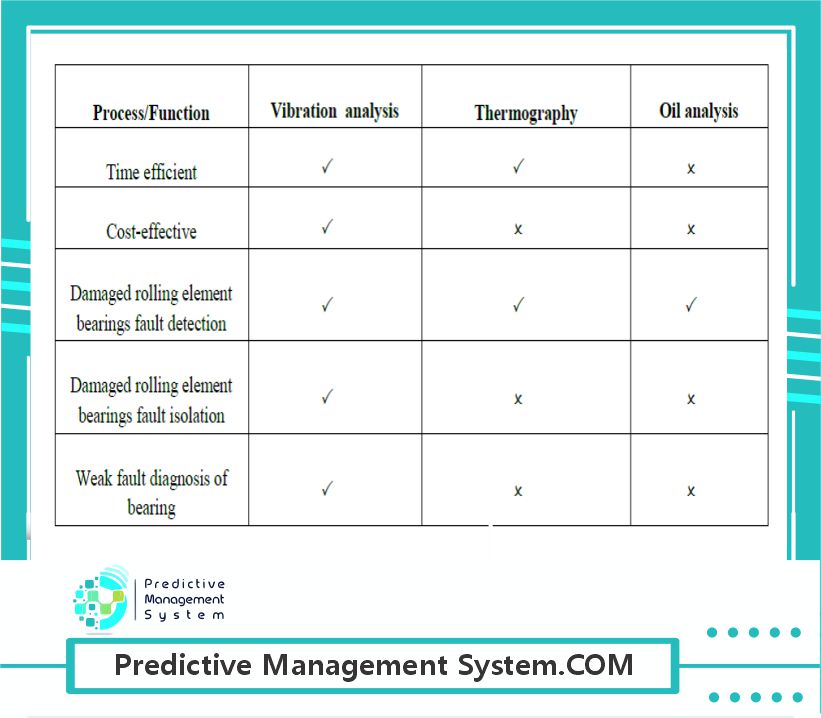

Obviously each method has some advantages briefed in the chart.